Lumber has 3 flaws you must consider when framing – Many Pro’s don’t Know This!

I grew up in the building industry. When I started with my grandfather’s company, there were no sub-contractors other than licensed trades (electricians, plumbers, HVAC). We built everything from the foundation to the shingles. This DIY series will offer tips and secrets the masters in the industry use every day. Some of these tips are guarded but others are unknown to most artisans today. God Makes Lumber – We Make it Straight!

Several years ago I contracted a frame project from a wealthy businessman who fancied himself a part-time builder. He invited me out to his project site to discuss the framing portion of his project. Upon arriving, I saw a crew busily constructing the outer walls with foam and steel rods. The process is known by many names, but it is usually called ICF (Insulated Concrete Forms). My new client was deeply interested in any alternative building technique that offered energy efficiency, sustainability and, more importantly, was cool. (By that I mean nifty.)

He told me the exterior walls would be poured the following week and he wanted to get the frame materials dropped asap for framing the interior walls. I shared with him my availability allowed me to start in his time frame. He then looked at me and asked if I did metal framing. I replied that I had many times. He smiled gratefully then asked me if he should use 25 gauge studs or 18 to 20 gauge structural studs. I replied,”Is there a commercial project you are doing in addition to this one?” He laughed and told me he didn’t like to use lumber because it wasn’t straight. My reply was serious and to the point: “Mr. Jones, God makes lumber – we make it straight.” After we discussed the difference in price between steel and wooden components, he became more interested in lumber for his project.

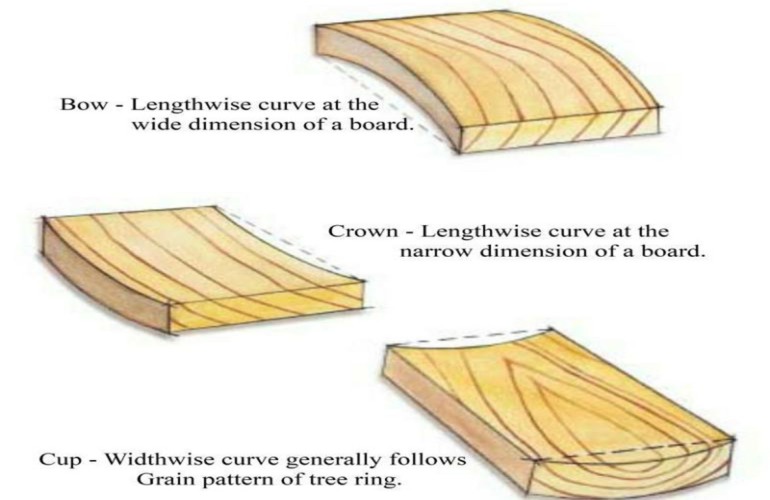

Lumber Has 3 Flaws we Carpenters take into Consideration Every Time we Build

When I framed for a living, the chief lesson I had to teach experienced carpenters was to crown and cup the material. Have you ever looked down a wall and noticed a wavy look to the sheetrock? Have you ever seen a wooden deck where the deck boards seemed to have formed a “U” in the center? If so, you have seen the result of carpentry work that was unmindful of the natural flaws of lumber.

When you frame a wall, you lay out the top and bottom plates, then place your wall studs at the layout marks with the crown up. There are always variations as to how much crown a stud will have compared to another. The goal is to make sure that all of the crowns go in one direction. This practice eliminates most of the wavy look in a finished wall. If you want a truly straight wall, add mid-blocking. Code requires fire-blocking on walls 10′ tall and higher. I mid-block every wall I build because as lumber dries and ages, it moves, exaggerating the crown, cup and bow.

A customer who was a fan of steel construction complained to me that he liked steel better than wood because 'wood is not straight.' I replied, God Makes Wood. We make it straight.